Insulating around a circuit breaker box is a crucial task that can significantly improve the energy efficiency of your home, reduce drafts, and enhance safety. However, it’s a task that involves dealing with electrical components and requires careful attention to detail and adherence to safety guidelines. This article will provide a comprehensive guide on how to insulate around a circuit breaker box safely and effectively.

To insulate around a circuit breaker box, first turn off the power for safety. Identify where cold air is entering, typically around gaps in the box, and use a fire-resistant insulating foam to seal these areas. If there’s a gap at the back, spray foam can be used to fill it. Be careful not to cover any ventilation openings or obstruct access to the box. After insulating, monitor the temperature around the box to ensure it does not overheat. Always consult a professional if unsure.

Why Insulate Around a Circuit Breaker Box?

Insulating around a circuit breaker box is essential for several reasons. First, it helps improve the energy efficiency of your home by preventing drafts and air leaks, which can lead to energy loss. Second, proper insulation can help prevent electrical fires by minimizing the amount of air that can flow around the box, potentially fueling flames and spreading smoke in the event of a fire. Furthermore, it can help prevent pests from entering your home through the gaps and openings around the box. Lastly, insulating around the circuit breaker box can help maintain a more consistent temperature in your home, making your living space more comfortable.

Materials for Insulating a Circuit Breaker Box

When choosing materials to insulate around a circuit breaker box, it’s important to select those that are safe, effective, and non-conductive. Some suitable materials include:

- Insulating foam: Products like Great Stuff or Firestop can be used to seal the gaps around the breaker box and prevent cold air from entering.

- Rigid foam insulation: This can be used to insulate electrical boxes. These materials provide good thermal resistance and reduce heat conduction through structural elements.

- Polycarbonate: This is a common material for indoor electrical boxes due to its affordability, good electrical insulation properties, and ease of modification.

- Polyurethane and polyisocyanurate foam: These materials are considered the best for thermally insulated electrical enclosures due to their high strength-to-weight ratio and superior thermal insulating value.

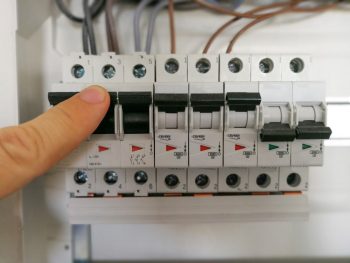

Steps to Insulate Around a Circuit Breaker Box

Here’s a step-by-step guide on how to insulate around a circuit breaker box:

- Turn off the power: Always ensure that the power to the breaker box is off to ensure safety while working around it.

- Inspect the area: Identify areas where cold air is entering, such as gaps around the box or where the main electric cable enters the box.

- Use insulating foam: Use a fire-resistant insulating foam to seal the gaps around the breaker box.

- Spray foam behind the box: If there is a gap between the rear of the circuit breaker box and the exterior wall, you can spray foam behind the box to fill the gap and provide insulation.

- Build a ‘picture frame’: If you need to insulate around the electrical panel, build a “picture frame” around the box by building out the wall framing enough to accommodate a piece of foam insulating board.

- Avoid covering ventilation openings: Be cautious not to cover any ventilation openings or obstruct access to the breaker box while insulating.

- Monitor the temperature: After insulating, monitor the temperature around the breaker box to ensure it does not overheat.

Always follow safety precautions while working around electrical components and consult a professional electrician if you are unsure about any steps in the process.

Dangers of Improper Insulation

Improper insulation around a circuit breaker box can lead to several issues, including overheating, damaged wiring, equipment failure, increased electrical resistance, and even fire hazards. It’s crucial to ensure that the insulation work is done correctly and safely to avoid these risks.

Conclusion

Insulating around a circuit breaker box is a task that requires careful attention to detail and adherence to safety guidelines. However, with the right materials and techniques, it can be done effectively and safely, improving the energy efficiency of your home, reducing drafts, and enhancing safety. Always consult a professional if you are unsure about any part of the process.

Frequently Asked Questions

What other safety precautions should I take when insulating around a circuit breaker box?

Always wear safety glasses and gloves to protect your eyes and hands while working. If you’re using spray foam insulation, you should also consider wearing a mask to prevent inhalation of harmful fumes.

Can I use regular insulation materials like fiberglass around a circuit breaker box?

No, you should avoid using conductive materials like fiberglass insulation around the box. Instead, use non-conductive insulating materials like fire-resistant foam or rigid foam insulation.

How often should I check the temperature around the circuit breaker box after insulation?

It’s recommended to monitor the temperature around the circuit breaker box for a few days after the insulation process. If the temperature remains stable, you can then check it monthly or anytime you suspect overheating.

Can I insulate the circuit breaker box myself, or should I hire a professional?

If you’re comfortable with DIY projects and understand the safety precautions, you can insulate the box yourself. However, if you’re unsure or uncomfortable working around electrical components, it’s best to hire a professional electrician.

Is it necessary to insulate around the circuit breaker box in all homes?

Insulating around a circuit breaker box is particularly beneficial in homes located in cold climates, where drafts and cold air can easily enter through gaps around the box. However, it can also help improve energy efficiency and safety in any home, regardless of the climate.