Have you ever wondered why your air conditioner seems to lose its cooling power after a few years?

The answer could lie in the corrosion of your AC coils. Corrosion is a common problem that can affect the performance and efficiency of your AC system.

If left unchecked, it can lead to costly repairs or even the replacement of the entire unit.

However, with the right preventive measures, you can protect your AC coils from corrosion and ensure that your cooling system lasts for many years.

So, if you want to keep your AC at peak performance and save money in the long run, read on to learn how to protect your AC coils from corrosion.

Here are a few key points discussed in this article:

- AC coil corrosion is a common problem affecting the system’s performance, leading to reduced efficiency, increased energy bills, and even system failure.

- Corrosion is caused by a combination of factors, including exposure to moisture, air pollutants, and certain cleaning chemicals.

- Common signs of corrosion include reduced airflow, warm air, and hissing or gurgling sounds.

- Regular maintenance, proper installation, ventilation, and air cleaners can help prevent corrosion and prolong the lifespan of your AC coils.

- Protective coatings can also be applied to AC coils as a barrier against moisture and pollutants. Some common types of protective coatings include epoxy, polymer, and Polyurethane.

- If you suspect your coils are already damaged, contact a licensed HVAC technician for a professional inspection and repair.

In this guide, we’ll walk you through the process of protecting your coils from corrosion, including identifying the common causes of corrosion, regular maintenance tips, and other preventive measures to keep your AC running smoothly all year round.

We’ll also discuss some common signs of AC coil corrosion and what to do if you suspect your coils are already damaged. By the end of this guide, you’ll understand how to keep your AC coils in top condition, helping you save money on future repairs and replacements.

So, without any further ado, let’s get started!

What Causes AC Coil Corrosion?

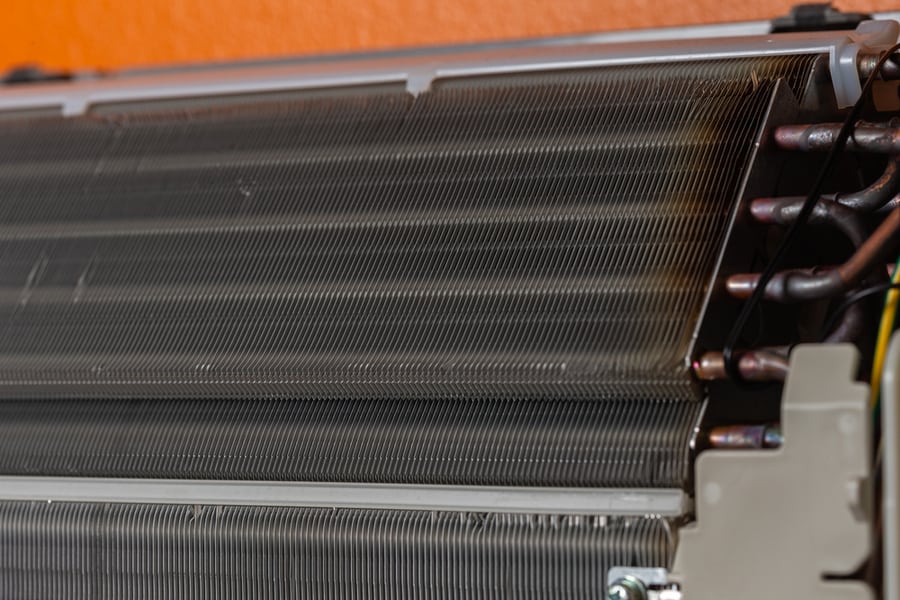

Ac coil corrosion is a common problem due to various factors. Moisture and pollutants in the air are the primary cause of corrosion.

As the air circulates through the AC unit, it brings moisture, dirt, and other pollutants that can settle on the coils.

When these contaminants accumulate on the coils, they form a layer that traps moisture and creates a perfect breeding ground for corrosion.

Poor ventilation is another factor that contributes to corrosion. When an AC unit is installed in a poorly ventilated area, it can accumulate moisture and pollutants, which can quickly cause corrosion.

In addition, exposure to harsh chemicals can also cause corrosion. Ac coils can come into contact with chemicals from cleaning products or other sources, leading to corrosion.

Finally, poor maintenance practices can contribute to AC coil corrosion. When the AC unit is not regularly cleaned and maintained, contaminants can build up on the coils, leading to corrosion.

Additionally, neglecting to replace air filters can cause dust and debris to accumulate on the coils, leading to corrosion over time.

It is essential to understand these causes to prevent corrosion from occurring in the first place.

What Are the Most Common Types of AC Coil Corrosion?

There are three main types of AC coil corrosion:

1. Formicary Corrosion

Formicary corrosion is caused by organic acids in the air, which react with the copper in the AC coil and cause it to deteriorate over time.

This type of corrosion can occur in indoor and outdoor Ac units and is often associated with poor air filtration or exposure to high humidity levels.

Formicary corrosion can cause small holes in the AC coil, leading to refrigerant leaks and reduced efficiency.

2. Galvanic Corrosion

Galvanic corrosion occurs when two dissimilar metals come into contact in an electrolyte, such as water or salt.

In an AC unit, galvanic corrosion can occur when copper and aluminum components come into contact with each other, leading to the deterioration of the aluminum and reduced efficiency of the AC unit.

Galvanic corrosion can also cause small pits on the surface of the AC coil, which can further accelerate the corrosion process.

3. Pitting Corrosion

Pitting corrosion occurs when the surface of the AC coil becomes damaged or compromised, allowing for the penetration of moisture, pollutants, and other corrosive agents.

Over time, this can lead to small pits or holes on the coil’s surface, further accelerating the corrosion process.

Pitting corrosion is often associated with exposure to harsh chemicals, extreme temperatures, and poor maintenance practices.

It is important to note that all types of AC coil corrosion can have serious consequences if left unchecked.

By understanding the causes and types of corrosion, you can take proactive measures to prevent it from occurring and keep your AC system running efficiently.

How To Protect AC Coils From Corrosion?

Now that you know what causes corrosion and its types, you can take steps to prevent it from occurring in the first place.

Here are some steps you can take to protect your AC coils from corrosion:

1. Regular Maintenance

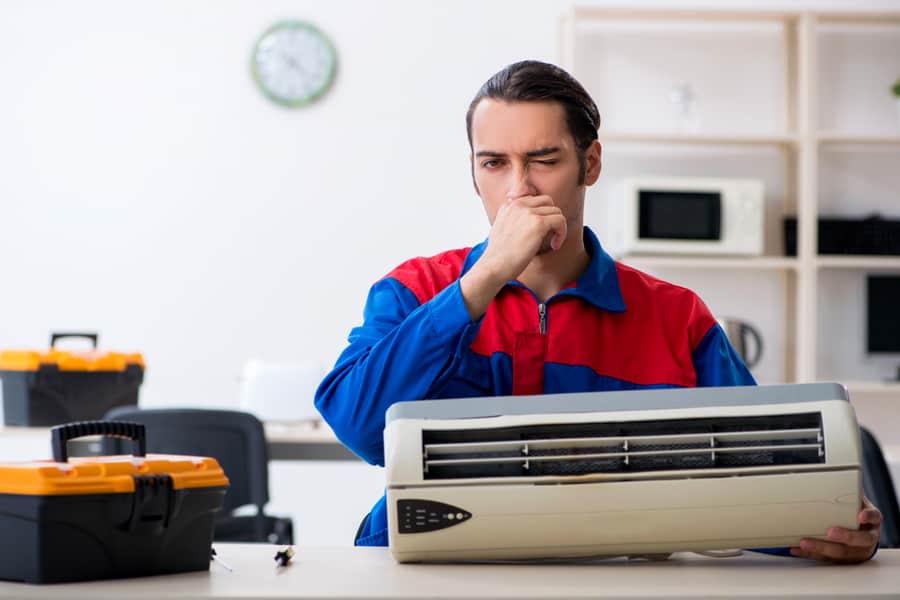

Regular maintenance is essential to catch any signs of corrosion early. Schedule an annual maintenance check-up with a licensed HVAC technician to ensure your AC functions correctly.

During the maintenance check, the technician will inspect the coils, clean them, and replace the air filters if needed.

2. Proper Installation

Proper installation of your AC unit is essential to prevent corrosion.

Ensure that your AC unit is installed in a well-ventilated area, away from sources of harsh chemicals, and where it is unlikely to come in contact with moisture.

3. Use Protective Coatings

Applying a protective coating to your AC coils can help prevent corrosion. These coatings are a barrier against moisture and pollutants, protecting the coils from damage.

4. Regular Cleaning

Regularly cleaning your AC coils can help prevent the buildup of contaminants that can cause corrosion. Use a soft-bristled brush or a vacuum cleaner with a brush attachment to remove dirt and debris from the coils.

Avoid using harsh chemicals or abrasive cleaning tools that can damage the coils.

By taking these preventive measures, you can protect your AC coils from corrosion and ensure that your cooling system runs efficiently for years.

It is crucial to address any signs of corrosion as soon as possible to prevent further damage and costly repairs or replacements.

Types of Protective Coatings for AC Coils

Several types of protective coatings can be applied to AC coils to improve their durability and performance.

Here are a few examples:

1. Epoxy Coatings

These coatings provide excellent corrosion resistance and can protect AC coils from damage caused by harsh weather conditions, chemicals, and other environmental factors.

2. Polymer Coatings

Polymer coatings are known for their high adhesion strength, which helps to prevent peeling and chipping. They also resist UV light and protect coils from fading or discoloration.

3. Polyurethane Coatings

Polyurethane coatings are often used in industrial settings because they can withstand high temperatures and resist abrasion. They also offer good resistance to chemicals and solvents.

4. Ceramic Coatings

Ceramic coatings are known for their durability and hardness. This makes them an excellent choice for protecting AC coils from wear and tear.

They are also corrosion-resistant and provide a high level of thermal insulation.

When selecting a protective coating for your coils, it’s essential to consider factors such as the type of AC unit, the environment in which it is installed, and the level of protection required.

Consulting with a licensed HVAC technician can help determine which coating type best suits your needs.

Remember, applying a protective coating to your AC coil is just one of many steps you can take to prevent corrosion.

Signs of AC Coils Corrosion and What To Do About It

Here are some common signs of AC coils corrosion and what you can do if you suspect your coils are already damaged:

1. Reduced Cooling Performance

If your air conditioning system is not cooling your home as effectively as it once did, it could be a sign of coil corrosion.

Corrosion can lead to blockages or damage to the coil, resulting in reduced cooling performance.

2. Strange Noises

A corroded AC coil may produce strange noises, such as hissing or gurgling. A refrigerant leak from the damaged coil could cause these noises.

3. Refrigerant Leaks

If you see fluid pooling around your AC unit, it could be a sign of a refrigerant leak. Corrosion can cause the coils to crack or develop holes, leading to refrigerant leaks.

4. Foul Odors

A corroded AC coil can also produce foul odors, such as a musty smell. This could be a sign of mold or mildew growth on the coils.

If you suspect your AC coils are damaged, contacting a licensed HVAC technician immediately is important. They can inspect your system and determine the extent of the damage.

Depending on the severity of the corrosion, the technician may recommend replacing the coils or the entire conditioning system.

Coil corrosion can significantly impact the performance of an AC unit by reducing its efficiency and increasing energy costs.

Sometimes, corrosion can also cause damage to the coils and other components of the system, leading to costly repairs or even the need for a full system replacement.

Moreover, corroded coils can lead to poor indoor air quality and potentially cause health problems.

Conclusion

In conclusion, coil corrosion is a serious issue that can significantly impact the performance and lifespan of your AC unit.

Taking preventive measures such as regular maintenance, proper installation, and cleaning can go a long way in preventing corrosion from occurring in the first place.

If you suspect your coils are already damaged, taking action immediately is important to prevent further damage and avoid costly repairs or replacements.

By working with a licensed HVAC technician and following these preventive measures, you can ensure that your AC unit has continued functioning properly and efficiently for years.

If you have any further questions, don’t hesitate to contact us. We are always here to help!

Frequently Asked Questions

Is It Normal for AC Coils to Rust?

Yes, it is normal for AC coils to rust, especially for older units. Over time, exposure to moisture and contaminants can cause corrosion on the coils.

However, with regular maintenance and proper care, the lifespan of the coils can be extended, and the risk of corrosion can be minimized.

How Long Should an AC Coil Last?

On average, AC coils can last anywhere from 15 to 20 years. However, the lifespan of the coils can vary depending on the factors such as usage, maintenance, and environmental conditions.

How Long Does a Protective Coating on AC Coils Last?

The longevity of a protective coating on AC coils varies depending on the type of coating, environmental conditions, and usage. Generally, a protective coating can last anywhere from 3 to 5 years.

However, it is important to note that regular maintenance and cleaning of the AC unit is still necessary to prevent corrosion, even with a protective coating.